How to Install and Inspect Needle Roller Bearings

In today’s blog post, we’re going to take a look at needle roller bearings, and what you need to know to properly install and inspect these pieces of equipment to ensure long life and high performance.

Installation Procedures

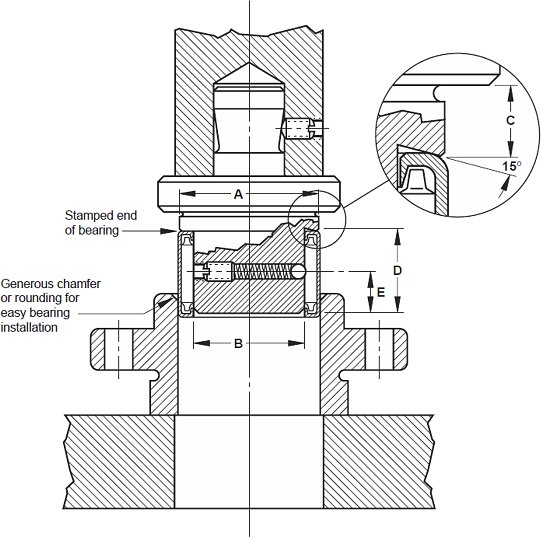

A drawn cup bearing must be pressed into the housing and an installation tool must be used in conjunction with a standard press.

It is advisable to utilize a positive stop on the press tool to locate the bearing properly in the housing. The assembly tool should have a leader or pilot, as shown, to aid in starting the bearing true in the housing. The installation tool must be coaxial with the housing bore. A ball detent is used to assist in aligning the rollers of a full complement bearing during installation and to hold the needle roller bearing on the installation tool.

How to install a neddle roller bearing

Assemble the needle roller bearing with the stamped end (with identification markings) against the angled shoulder of the pressing tool. Never hammer the bearing into its housing even in conjunction with the proper assembly mandrel or press the bearing tightly against a shoulder in the housing.

If it is necessary to use a shouldered housing, the depth of the housing bore must be sufficient to ensure the housing shoulder fillet, as well as the shoulder face, clears the bearing.

Inspection Procedures

Although the bearing cup (outer ring) is accurately drawn from strip steel it may go out of round during heat treatment. When the bearing is pressed into a true round housing or ring gauge of correct size and wall thickness, it becomes round and is sized properly. For this reason, it is incorrect to inspect an unmounted drawn cup bearing by measuring the O.D. The correct method for inspecting the bearing size is to:

- Press the bearing into a ring gauge of proper size.

- Plug the bearing bore with the appropriate “go” and “no go” gauges.

The dimensions of the correct ring and plug gauge diameters for inspecting drawn cup needle roller bearings are available from the AST Bearings technical department upon request, contact them here for this or any of your bearing questions.