Bearings For Handheld Power Tools

Hand held power tools are an $11 billion industry in the US and a $26 billion industry worldwide, with strong consumer and professional segments. It is crucial that the components within these products meet and exceed the industry standards to ensure that they perform as designed, and ball bearings play a critical role in this performance and reliability.

The bearings for handheld power tools must be able to handle combined loading conditions, high-speed operation, low friction, low noise and vibration, and high reliability.

Bearings Catalog

Check out our online product catalog with more than 10,000 products with full specifications & 3D CAD Models available for download - all free of charge!

Below are some considerations that apply specifically to the bearings within hand held power tools:

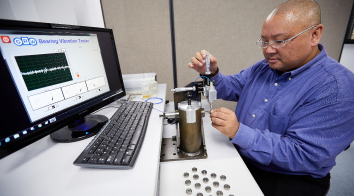

Noise and Vibration: A noisy and vibrating tool will quickly cause discomfort for its operator, particularly in factory or production environments where motion and operations are repetitive. In the case of ball bearings, noise and vibration are directly related to the quality of the materials used for the rings and balls, the internal manufacturing specifications and tight process controls.

Ball bearings for power tools, due to their internal construction, can support both radial and axial loads simultaneously, making them the ideal choice for the demands of power tools, however it is important that the bearings are preloaded to remove radial play, which can cause noise and vibration during use.

Running Temperature: Because power hand tools must be designed and manufactured to run and be held comfortably by an operator for long periods of time, it is crucial that the necessary steps are taken to reduce the amount of heat produced by the bearings during use. These steps include ensuring proper mounting, preload and lubrication.

Bearing Materials: In order to attain the highest levels of fatigue strength and wear resistance, bearings should be produced with high purity materials, such as SAE 52100 chrome steel. Although SAE 52100 chrome steel is the most effective choice for most power hand tools, if the tool is exposed to corrosive or moisture then martensitic stainless steel is recommended.

Lubrication: Lubication plays a crucial role in a number of areas including noise, vibration, and running temperature. Not all lubricants are made alike, and there are thousands of variations available. While NLGI grade 2 greases are suitable for most tools, here are some characteristics that are desirable for greases used with power hand tool bearings:

- Resistance to aging and oxidation

- Excellent mechanical shear stability

- Excellent corrosion resistance, even in the presence of water or moisture

- Low noise properties

Harsh Environments: It is common that power hand tools used in industrial environments are frequently exposed to harsh environments with debris and moisture of varying types. For this reason, sealed or shielded bearings should be used whenever possible. Shields are preferred insofar as they provide protection for the bearing from contaminants without affecting the speed capability. While seals offer greater protection from debris, they reduce the maximum speed capacity of the bearing.

Ask A Question

Ask us a question and one of our team members will respond as soon as possible.

Fields marked with * are required.

.webp)

%20(1)%20(1).webp)

.webp)