Our last installment of this discussion took a deep dive into lubricant selection criteria. In Part 3, we examine factors affecting shelf life and various lubrication regimes, both important considerations when choosing a lubricant. The following is Part 3 of a five-part post. You can read Part 2 here and Part 1 here.

Shelf Life

Shelf life is the period following the lubricant’s manufacture during which it is deemed suitable for use without re-testing its physical characteristics. Synthetic oils are inherently stable materials. Generally, they are not expected to oxidize, polymerize or volatilize at room temperature for 10 years or more. Ester oils, where the ester linkage may be subject to a minute degree of hydrolysis in the presence of moisture, could become more acidic if moisture is present. Fluorinated oils and silicones are not likely to be affected by simple aging.

Greases can "age" in more complicated ways. Grease quality could be affected by a change in the gel structure. If the gel contracts, significant oil bleed would be evident and the remaining grease would stiffen. The gel structure may also become softer over a period of time.

High-quality lubricants are essential to ensure optimum bearing performance and many are qualified to military or other specifications. When the designer does not specify the type and quantity of lubricant, bearings are lubricated to conform to industry standards.

Manufacturers state that the shelf life applies only if oils and greases are properly stored in their original, unopened containers.

Lubrication Regimes

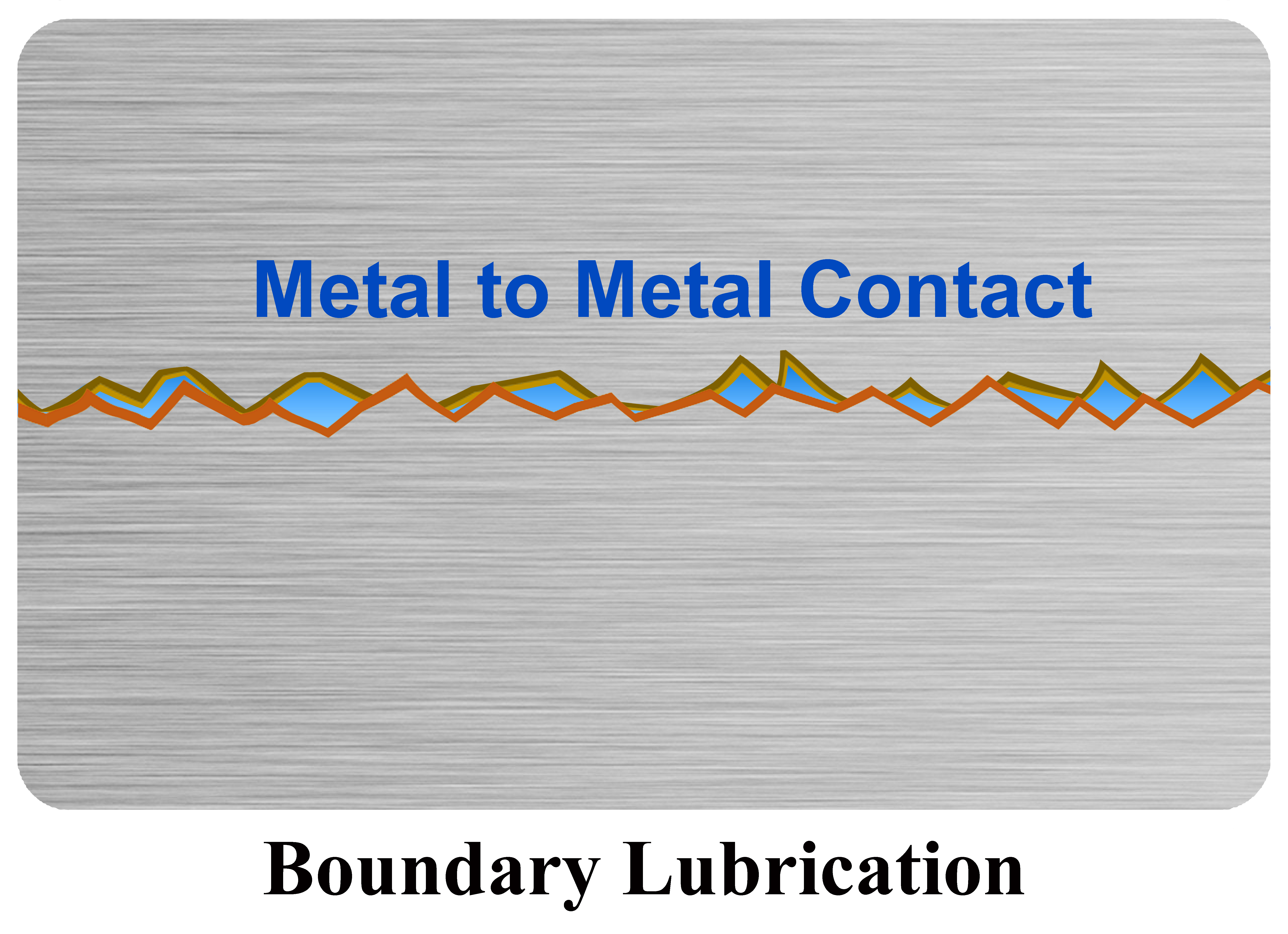

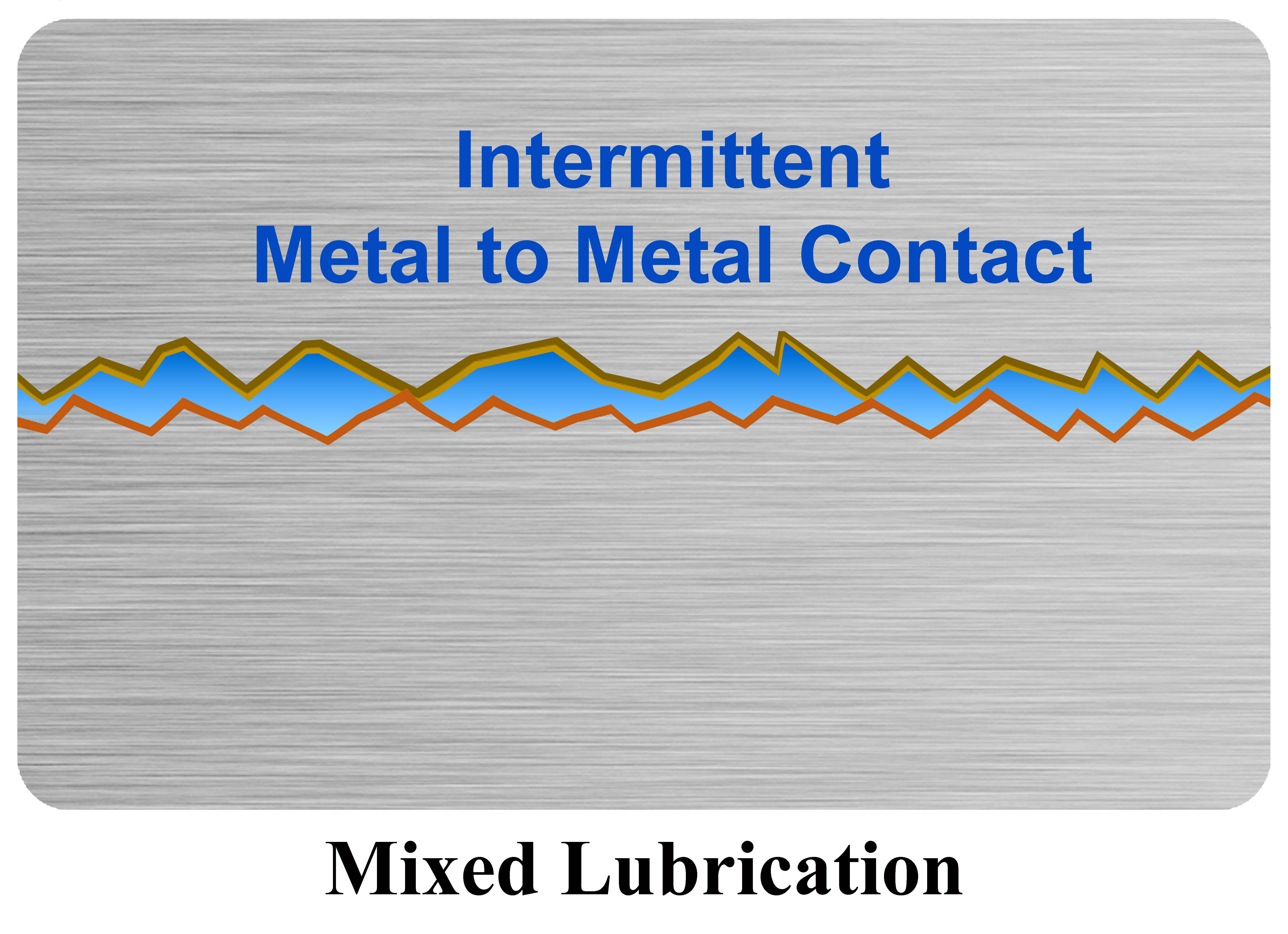

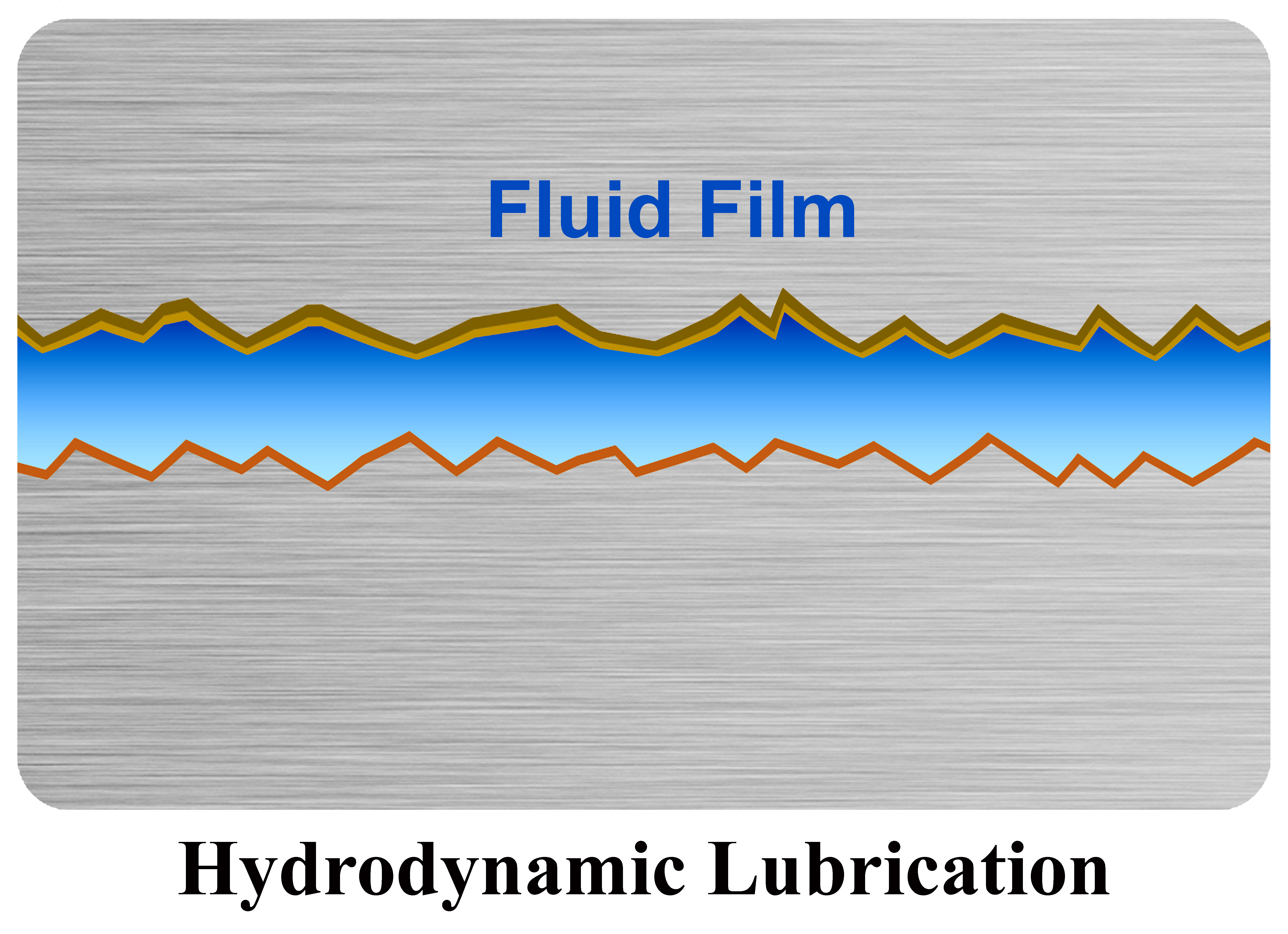

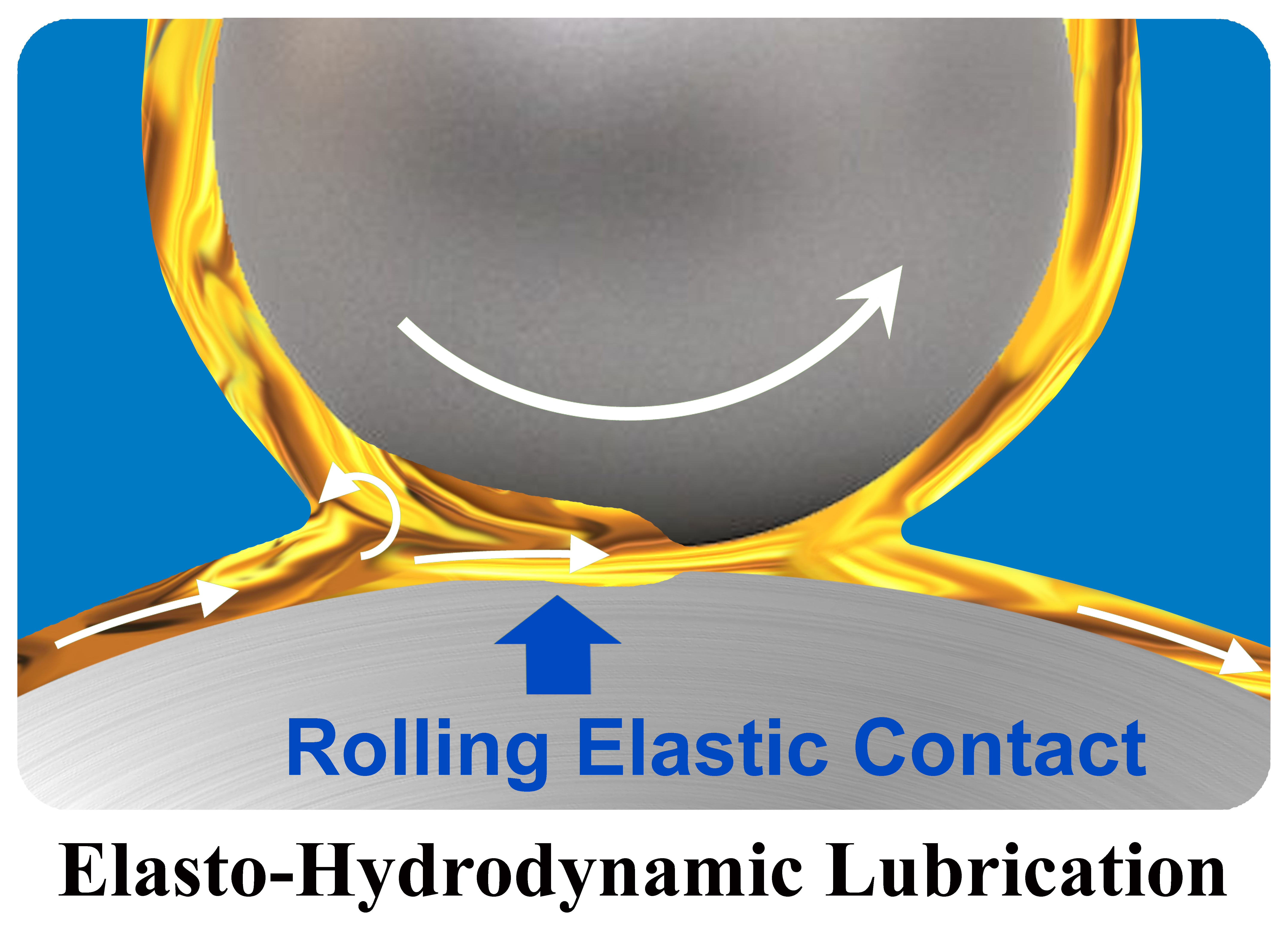

The thickness of the fluid film determines the lubrication regime, or the type of lubrication. The basic regimes of fluid film lubrication are:

● Hydrodynamic Lubrication - Two surfaces are separated by a fluid film.

● Elasto-Hydrodynamic Lubrication (EHL) - Two surfaces are separated by a very thin fluid film.

● Mixed Lubrication - Two surfaces are partly separated, partly in contact.

● Boundary Lubrication - Two surfaces mostly are in contact with each other even though a fluid is present.

In addition to fluid film lubrication, there is solid film lubrication, in which a thin solid film separates two surfaces.

Our next installment in this educational discussion focuses on film formation and the Stribeck Curve. Look for Lubrication for Life – Part 4 coming November 13.