Rolling Bearing Lubrication Services

Bearing lubrication services play a vital role in the performance and life of rolling element bearings. A bearing lubricant that is designed for specific operating conditions will provide a load-bearing wear protective film. The ideal condition is when the friction surfaces are separated by this film. In addition to providing this load-bearing film, the lubricant should also allow for the dissipation of frictional heat thus preventing overheating of the bearing and deterioration of the lubricant and provide protection from corrosion, moisture, and the ingress of contaminants.

Bearings Catalog

Check out our online product catalog with more than 10,000 products with full specifications & 3D CAD Models available for download - all free of charge!

Bearing Re-lubrication Benefits

Bearings are often produced with a lubricant that is generic and doesn't cater to unique applications when ordered directly from a factory. Bearing relubrication services offer multiple benefits in the interest of time, availability, and the assurance of a suitable product. In some cases, lubricants break down before the bearings themselves, which is why re-lubrication is a valuable and cost-effective solution to keep your bearings running longer. In most cases, it is economical to relubricate a bearing rather than to scrap it and replace bearings altogether. Many of AST’s customers have unique applications that require specialty lubricants for their unique production needs, which is why custom lubricant is often created by AST. These are just some of the instances where bearing cleaning and re-lube can be the best solution.

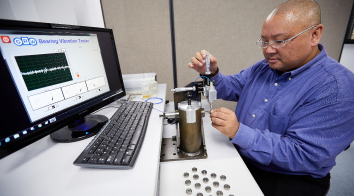

AST Bearings' Relubrication Facilities

Our New Jersey headquarters features one of the largest bearing lubrication facilities in the country including Class 10,000 clean rooms with ISO Class 5 laminar flow work benches within the Class 7 environment. Our lubrication specialists work with virtually hundreds of different lubricants, including those that are mil-spec qualified. We can also formulate custom lubricants to meet the needs of unusual applications.

Our facilities were designed specifically for the custom cleaning and relubrication of commercial and precision ball bearings. This facility is comprised of three separate units:

- GRAY ROOM: Employed for the preparation of bearings for the subsequent cleaning procedures, as well as the relubrication of commercial grade bearings.

- WASH ROOM: Houses all of the generic and proprietary cleaning equipment utilized in the processes of cleaning bearings in preparation for relubrication.

- CLEAN ROOM: A class 10,000 clean room facility with ISO Class 5 laminar flow work benches, both of which are Certified to Federal Standard 209E. This facility is utilized for the relubrication, testing and final inspection of precision ball bearings.

Our facilities process millions of ball bearings annually and routinely lubricate bearings with standard or exotic lubricants to exacting specifications.

Bearing Lubrication Specialty Services

AST Bearings also has a special proprietary lubrication process called "MicroGrade Grease Plate"™ (also called MGGP™) which is the solution to achieving low torque in precision bearings, without the problems generally associated with lubrication migration.

Ask A Question

Ask us a question and one of our team members will respond as soon as possible.

Fields marked with * are required.

.webp)

%20(1)%20(1).webp)

.webp)