Mechanical Sub-Assemblies

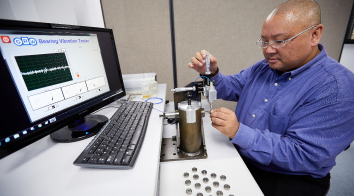

AST goes beyond supplying standard bearings, we also provide precision mechanical sub-assemblies. We specialize in rotary assemblies that incorporate precision bearings and components manufactured to the most exacting specifications. AST can conduct design reviews and provide assemblies manufactured to your specifications or ours. Our highly skilled technicians know the correct way to handle and install bearings and can provide you with a more reliable assembly at significant cost savings.

Bearings Catalog

Check out our online product catalog with more than 10,000 products with full specifications & 3D CAD Models available for download - all free of charge!

Mechanical Sub-Assemblies

- Tight tolerance machining, castings, injection molding

- Component materials: metals (various alloys) and plastics

- Specialty materials and lubricants

- Protective Coatings

- Commercial or super-precision bearings with precise quantities of lubrication

AST Mechanical Sub-Assembly Services

- Bearing engineering expertise (CAD drawings provided upon request)

- Contract assembly

- Class 100 and Class 10,000 assembly and test environments

- Product inspection and testing

- World-class bearing laboratory

- Low-cost sourcing

Some examples of AST’s mechanical sub assembly work are shown below:

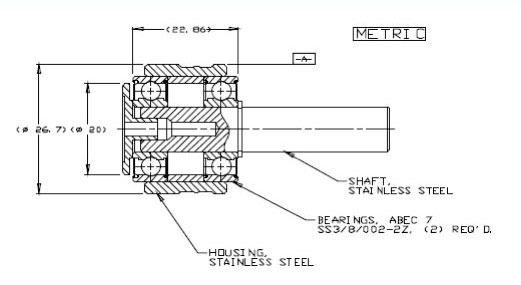

Precision Spindle Assembly for an Industrial Encoder

An encoder is a position sensing device. They are used to sense rotary motion and they provide feedback, via an electrical signal, to a processor, controller, or computer. Therefore they are used in automated machinery and test systems in conjunction with friction and measuring wheels, ball screws, timing pullies, rack and pinion actuation, etc.

Assembly Details:

- Bearings: Two stainless steel ball bearings, ABEC-7 precision with 2 shields and bonded under a pre-load.

- Shaft and Housing: Both made of stainless steel.

- Lubrication: Lubricated with a special grease for low noise and increased life

- End Result: A very precise running geometry

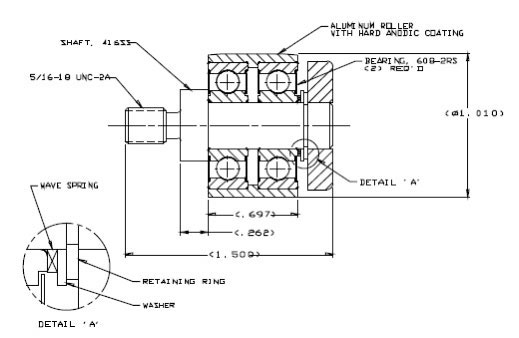

Pulley Assembly for Paper Transport System

AST's pulley assembly for paper transport comes ready to install…. As for Paper Transport Systems, AST provides a Pulley Assembly, which incorporates two (2) Chrome ABEC 3 bearings with PTFE seals in an anodized aluminum with a stainless steel shaft. This provides a low-cost, maintenance-free assembly for long life in a harsh paper dust environment.

Assembly Details:

- Bearings: Two chrome ball bearings, ABEC-3 precision with PTFE seals.

- Shaft: Stainless Steel

- Housing: Anodized aluminum

- End Result: A low-cost, maintenance free assembly for long life in a harsh, paper dust environment.

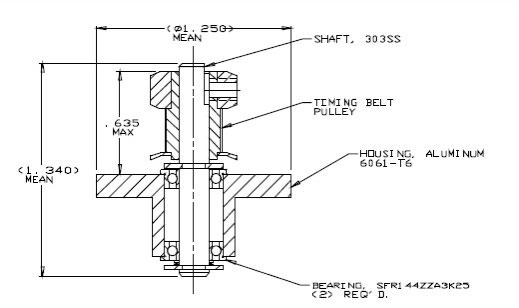

Timing Belt Idler Assembly

AST's timing belt idler assembly comes ready to install…. A series of timing pulley idler assemblies are rotary assemblies that incorporate precision bearings and components. The assemblies are used for applying pretension to timing belts in positioning systems and include two flanged miniature stainless-steel bearings pre-loaded with a wave spring, stainless steel shaft, and aluminum housing. Pulleys are available to accommodate various pitches and belt widths.

Assembly Details:

- Bearings: Two flanged miniature series made of stainless steel.

- Shaft: Stainless Steel pre-loaded with wave spring

- Housing and Pulley: Anodized aluminum

- End Result: This particular timing belt idler assembly was effectively and efficiently used in an Electronic Media Storage System.

AST Bearings is proudly presenting our new certificates for both the NJ and CA locations: AST Bearings’ ISO 9001:2015 Certificates

To learn more about what the ISO 9001 standard is, the differences between the 2015 and 2008 versions, and how AST verifies customer satisfaction: Learn About AST Bearings’ certification to ISO 9001:2015

Ask A Question

Ask us a question and one of our team members will respond as soon as possible.

Fields marked with * are required.

.webp)

%20(1)%20(1).webp)

.webp)