In the previous installment, we discussed the types of lubricants available for use with rolling-element ball bearings: oils, greases, and solid films. Here we will examine the issues you need to consider when selecting the optimum oil or grease lubricant for your application.

The following is Part 2 of a five-part post. You can read Part 1 here.

Selection Factors to Consider

Lubrication is one of the most critical specifications for the designer to consider. When selecting a lubricant, factors including temperature, loads, speed, environment, and desired life need to be examined. Additionally, there are many characteristics of greases and oils that should be considered such as oil separation, evaporative loss, dropping point, oxidation stability, channeling capability/stiffness, and others.

Grease is by far the most common lubricant selected for the radial ball bearings used in electric motors and gearboxes. Oils provide lower torque characteristics, but are subject to evaporative loss and migration and not always well suited for lifetime lubrication.

Grease Characteristics:

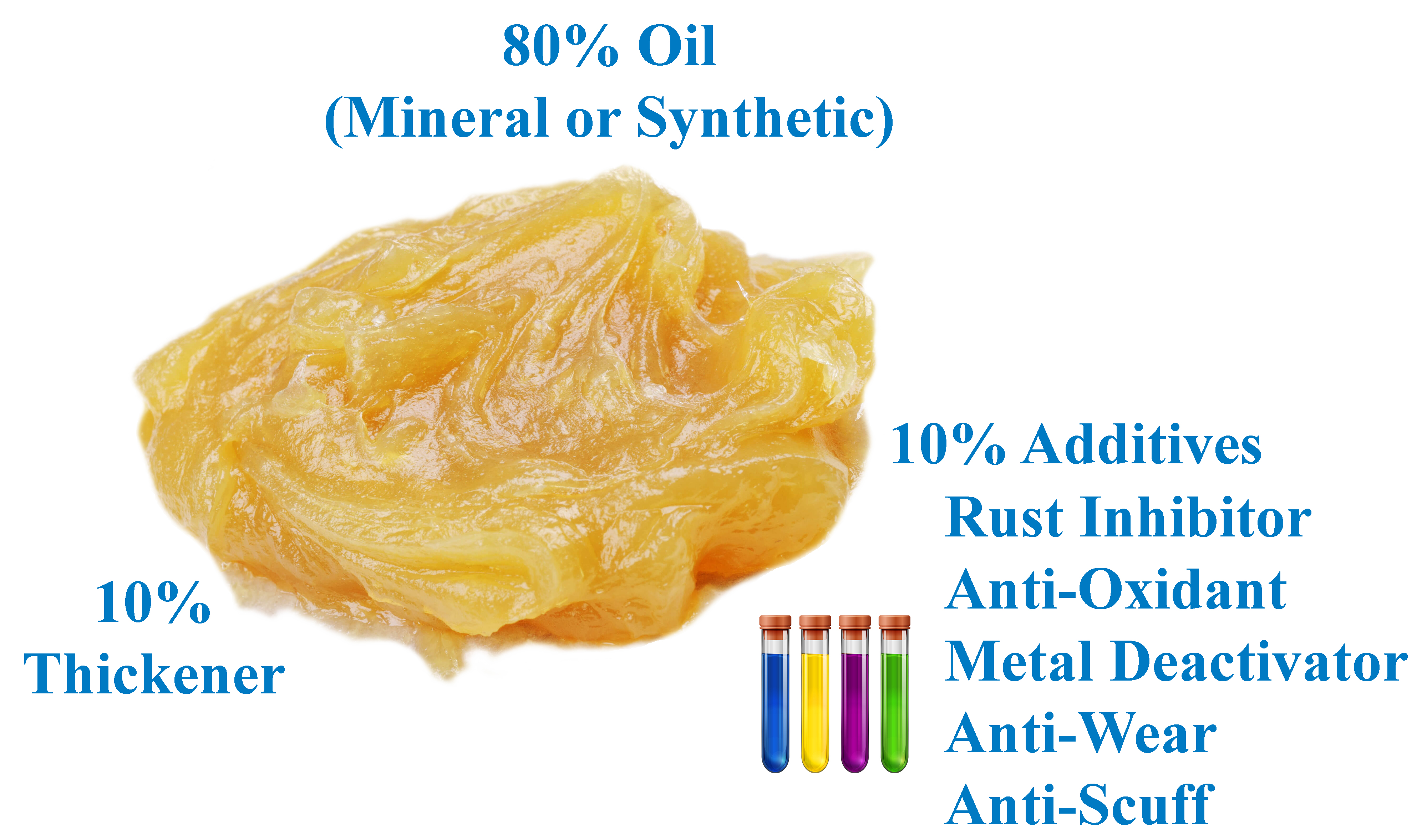

As previously mentioned, grease lubricants consist of a base oil, mineral or synthetic, combined with a thickener and typically other additives. The properties of a given grease are determined by these components, along with proper handling, storage of the raw materials, and good process control by the grease manufacturer.

Type of Base Oil:

Base oil viscosity is of primary consideration when evaluating a potential grease lubricant. Viscosity, the measure of “flowability”, is the resistance to flow caused by internal friction between the lubricant molecules. This characteristic determines load carrying capacity, film thickness, and operating temperature. The higher the viscosity, the higher the film strength. Viscosity varies as a function of temperature. The higher the temperature, the lower the viscosity. Therefore, it is very important to select lubricants based on temperature ranges in operation. Specialty high temp greases, specialty low temp greases, and greases with very wide temperature ranges are available to address specific temperature specifications.

Stiffness:

Greases are classified by their consistency, or stiffness. The ASTM has developed a test method for determining the stiffness of grease utilizing a cone of a prescribed weight and dimensions that is dropped into the sample of grease. The cone is withdrawn after 5 seconds and the depth of penetration is measured in tenths of a millimeter. The higher the number, the deeper the penetration and the softer the grease. The grease sample is then placed in a machine that strokes it (think of a mixer or egg beater for baking) to simulate operating conditions. It is then retested. This result is referred to as the worked penetration and is the basis for classification. The National Lubricating Grease Institute (NLGI) classifications are listed in the following table.

CLASSIFICATION OF GREASES BY NLGI CONSISTENCY NUMBERS

| NLGI NUMBER | ASTM WORKED PENETRATION |

| 000 | 445-475 |

| 00 | 400-430 |

| 0 | 355-385 |

| 1 | 310-340 |

| 2 | 265-295 |

| 3 | 220-250 |

| 4 | 175-205 |

| 5 | 130-160 |

| 6 | 85-115 |

The lower the NLGI number, the softer the grease. The lower the ASTM number, the stiffer the grease.

Thickeners

Greases consist of a solid soap such as calcium or lithium soap. In some cases, a fine clay is used that forms a structure in which base oil is held and dispersed. The thickener structure does not provide actual lubrication, but is a reservoir that releases lubricant to the contact area.

Thickeners, while not contributing much toward lubrication, impart unique properties to the grease affecting its applicability in certain applications or environments. Of these the lithium and lithium complex thickened greases are the most common.

- Lithium -- Most common, easy to manufacture, easy to store, good pumpability, flowability permits dirt to flow out

- Calcium -- Good water resistance, calcium soap aids lubrication

- Aluminum -- Highest resistance to water, chemicals, acids

- Barium -- High water resistance, but somewhat toxic

- Sodium -- Fibrous, water-soluble

Another class of thickeners is the non-soap thickeners. These are often used in applications where high temperatures are causing other types of thickeners to experience thermal degradation. The organic polyurea thickener offers temperature range limits similar to the metal soaps, but also has antioxidation and antiwear properties that come from the thickener itself.

- Clays and Silica (Insoluble powders, silica or platelets of clay) -- Chemically modified structures and surfaces are made usable as gelling agents for grease. These greases further increase the maximum usable temperature.

- Polyurea -- Polyurea greases are called high performance greases due to their broad range of performance attributes.

Additives

Greases can be fortified to contain boundary and EP additives, as well as solid lubricants such as graphite and molybdenum disulfide.

- Corrosion and Rust Inhibitors -- These are very common additives that prevent corrosion and rusting of metal parts in contact with the lubricant. These additives work by neutralizing acids and forming a chemical protective barrier to repel moisture from metal surfaces.

- Anti-wear (EP) -- Anti-wear additives and/or extreme pressure additives are chemical additives that protect metal surfaces during boundary lubrication. They form a protective film on the wear surfaces and react chemically with metal surfaces to form a sacrificial surface film. They are activated at high loads and high contact temperatures.

- Anti-oxidants: Anti-oxidants are found in most greases and oils. They prolong the life of the base oil. Oxidation attacks the base oil. While oxidation occurs at all temperatures all of the time, it accelerates as the temperature increases and in the presence of water, wear metals, and other contaminants.

- Viscosity Index (VI): These additives reduce the rate of change of viscosity with temperature.

- Pour Point: Pour Point additives improve low temperature operating range.

- Tackifiers: These additives help the lubricant adhere to the metal surface during rotational movement.

Other Considerations

- Amount: The lubricant amount selected also impacts the maximum operating speed and torque, both starting and running. Too much grease will often cause a bearing to run hot. Generally, as rotational speed increases the fill amount is reduced. Also, as loads increase, the fill amount is normally increased as well.

- Cleanliness: In miniature, or smaller, bearings the lubricant can impact the noise level. Filtered greases and oils are recommended for use with miniature or instrument bearings. Particle sizes larger than the lubricant film thickness will also lead to EHD film breakdown and generate wear debris. This can trigger a progressive process that leads to premature failure.

Stay tuned for more on the proper selection of a lubricant guided by AST engineers in Lubrication for Life – Part 3. Coming October 16.