Self-lubricating bushings are used where the bearing must operate without lubricant or with marginal lubricant.

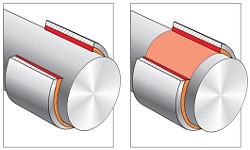

AST’s focus is on ensuring that the bearing gives the best performance and the longest life under various conditions. The working principle of self-lubricating bearings is that, during the initial run-in period of the bearing, there will be a solid lubricating film created by the transfer of a small amount of material from the bearing layer. This film directly contacts the moving parts, protecting and lubricating the mating components and extending the service life of the bearing.

Utilizing self-lubricating bushings can provide a number of benefits for end users to be aware of. These include:

- Elimination of oil holes and grooves – cost for machining oil holes and oil grooves is unnecessary. Self-lubricating eliminates the need for the extra oiling system.

- Reduction of the machinery running cost – with maintenance free features, the lubricant oil is dramatically reduced; machinery running cost will also be decreased.

- Maintenance-free operation – self-lubricating bearings solve the problem of oiling operation and oiling devices, also saving bearing maintenance costs.

- Simplified mechanical design and manufacture – with the above advantages, thin wall thickness, higher load, and excellent wear resistance, mechanical designs can be simplified and made more economical.

- Environmentally friendly – the self-lubricating bearing materials work without oil and meet the ROHS directive.

Looking for more information about self-lubricating bushings or another bearing product? Our team of bearing experts provide engineering consulting/design and are ready to provide assistance – contact them here.