What Are the Precision Levels Available for Ball and Roller Bearings?

Most applications involving radial bearings use one or more types of ball or roller bearings, which are available in various precision levels known as tolerance classes. To rate these tolerances uniformly, we use the ABEC and RBEC rating scales as the industry standards in the U.S.

For ball bearings, these tolerance classes are ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9. Similarly, the precision levels for roller bearings (both cylindrical and spherical) are RBEC 1, RBEC 3, RBEC 5, RBEC 7, and RBEC 9. A different rating scale is used for tapered roller bearings.

The ABEC and RBEC classes are identical in values: for both, the higher the class number, the tighter the bearing’s tolerances – thus the better the precision, efficiency, and speed capabilities of the bearing.

The ABEC (or RBEC) ratings specify tolerances of size and form for the individual inner and outer rings. Tolerances of size refer to the basic boundary dimensions: the inner diameter of the inner ring, the outer diameter of the outer ring, and the ring widths. Tolerances of form include roundness, taper, runout, and parallelism.

Determining the proper tolerance class for bearings in a particular application is very important. We encourage designers to adhere to the following general guidelines:

- Designers should always perform a tolerance stack-up study at both the maximum and minimum material conditions when sizing components, especially when designing for miniature ball bearings.

- Consider the different precision level options in terms of their direct correlation to bearing performance and lifespan. For example, raceway parallelism can affect bearing torque, so a non-parallel raceway condition will result in torque spikes during rotation. In high-speed applications, excessive bearing runout can result in an imbalance in the rotating mass. Both conditions can lead to unpredictable bearing life and premature failure.

- Keep in mind that the higher the precision level, the greater the cost of the bearing.

- Remember bearings with higher tolerance classes are intended for use in precision applications that require high running accuracy, high speed rotation, and/or low torque. Common examples include aircraft instruments, machine tool spindles, and dental equipment.

- On the other hand, bearings with lower tolerance classes are acceptable for use in a wide range of applications, such as automotive, electric motors, and most industrial machinery.

While our AST Bearings engineers are happy to guide you through tolerance class selection in the development of your application, the biggest takeaway to keep in mind during the initial design stage is this precaution: Using a lower tolerance class bearing than required by an application can (and often does) result in premature bearing failure. This results in increased downtime, high maintenance costs, loss of revenue, and in some extreme cases, personal injury or loss of life.

It can be tricky to weigh cost against the level of tolerance class required for acceptable performance; however, experts at companies like AST are here to help you solve your questions.

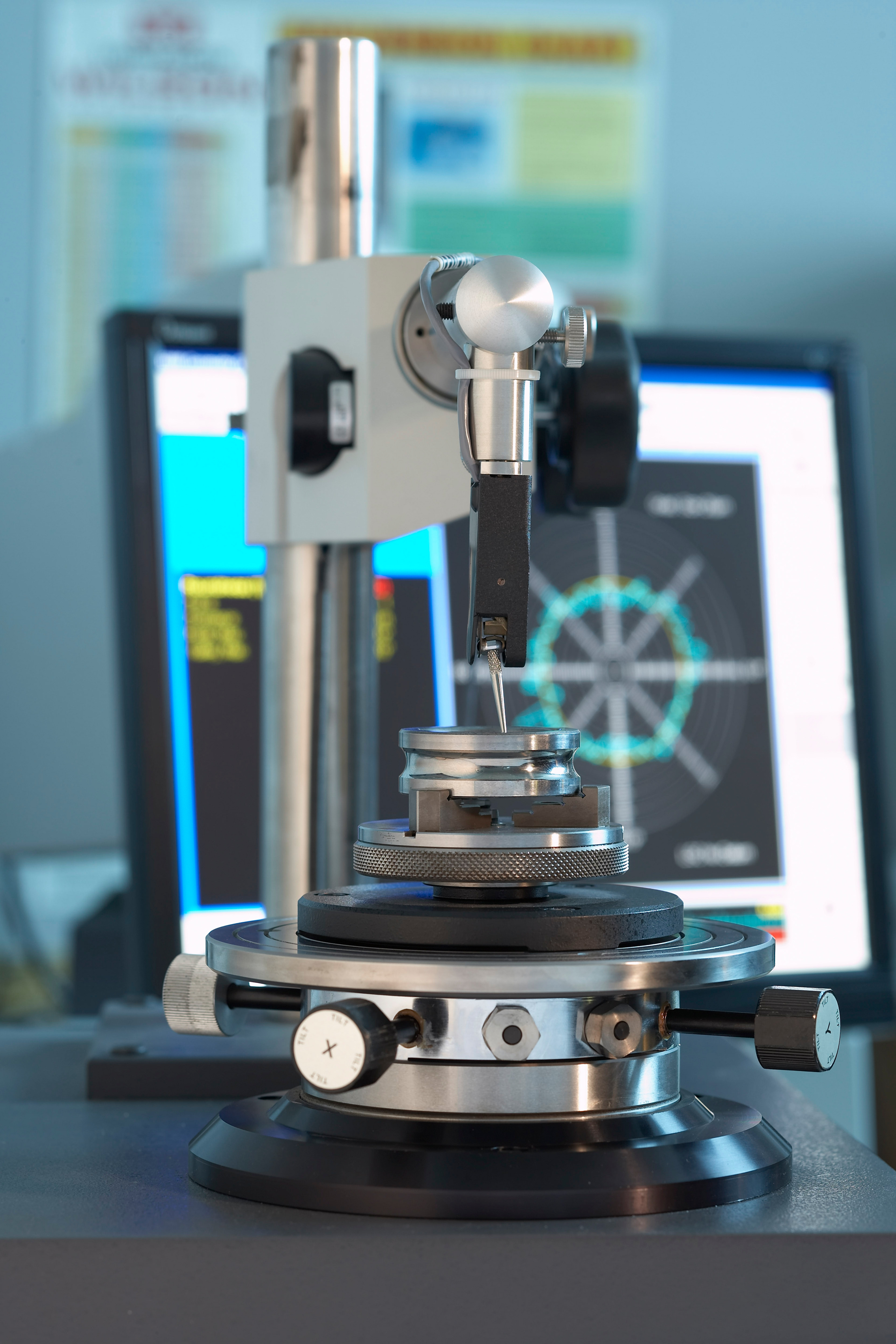

Measuring roundness of a bearing inner ring. Roundness is one of several important features to consider when selecting a tolerance class for a bearing.