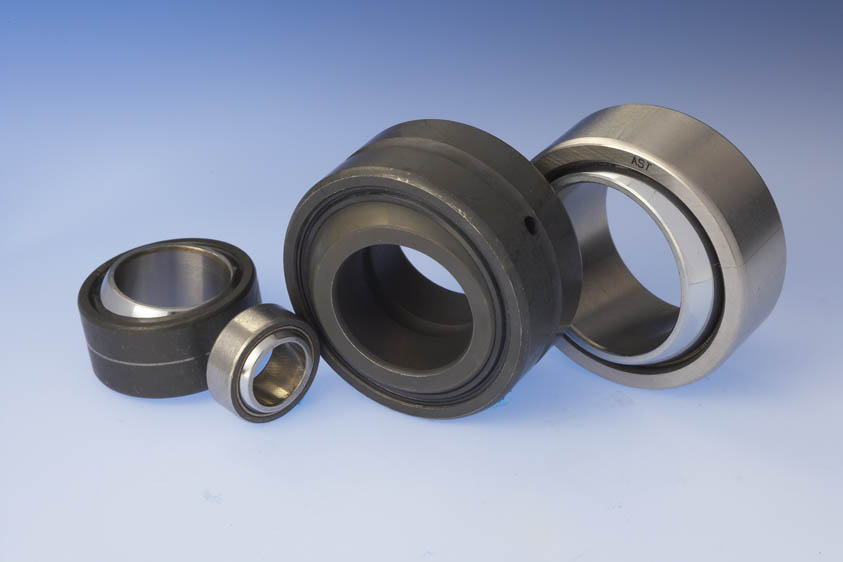

Spherical Plain Bearings - Overview

Radial spherical plain bearings have an inner ring with a sphered convex outside surface and an outer ring with a correspondingly sphered but concave inside surface. Their design makes them particularly suitable for bearing arrangements where alignment movements between shaft and housing have to be accommodated, or where oscillating or recurrent tilting or slewing movements must be permitted at relatively slow sliding speeds. They are available with different sliding contact surface combinations, i.e. the sliding surfaces of inner and outer rings are made from different materials. There are two main groups: spherical plain bearings requiring maintenance (steel-on-steel) and maintenance-free spherical plain bearings.

The radial spherical plain bearings requiring maintenance (steel-on-steel) have hardened sliding contact surface on both rings. The surfaces are treated with molybdenum disulphide (MoS2) lubrication and a phosphate coating. They have both wear and corrosion resistant characteristics. Bearings with this sliding contact surface combination require regular relubrication. The high strength of the sliding contact surfaces makes these bearings especially suitable for bearing arrangements where heavy loads of alternating direction, shock loads or heavy static loads have to be accommodated.

The maintenance-free spherical plain bearings sliding contact surfaces have three groups: steel-on-PTFE composite material, steel-on- PTFE fabric and steel-on-copper alloy. Dynamic load support capability of steel-on- PTFE fabric spherical plain bearings is higher than that of steel-on-PTFE composite material. They have very low friction and can be operated without maintenance. They are used for applications where long bearing lives are required without maintenance, or where operating conditions, such as inadequate lubrication or the absence of lubrication make the use of steel-on-steel bearing inadvisable.

Design Characteristics and Materials

The radial spherical plain bearings requiring maintenance (steel-on-steel) can be made with outer rings made of hardened carbon chromium steel or carbon steel. Those made with hardened chromium carbon steel will have either axial or radial split(s) to accommodate ball entry. Carbon steel outer rings will be pressed around the inner ring. Inner rings of maintenance requiring spherical plain bearings are made of hardened carbon chromium steel.

The sliding surfaces between these types of spherical plain bearings could have molybdenum disulphide (MoS2), hard chromium plating, or a bronze liner to reduce wear. Outer and inner rings can be phosphate coated to increase corrosion resistance. These bearings are available with an annular groove and lubrication holes. Some bearing designs can also be fitted with seals to keep out contamination.

Variations with multiple split outer rings can be fitted with retaining rings. Spacers and extended inner ring also available, contact AST engineered for assistance.

Click on each below to learn more about the variations of steel-on-steel spherical plain bearings:

Maintenance-Free Type Spherical Plain Bearings

The radial spherical plain bearings not requiring maintenance can be made with outer rings made of hardened carbon chromium steel, carbon steel, or hardened stainless steel. Those made with hardened chromium carbon steel or stainless steel will have either axial or radial split(s) to accommodate ball entry. Carbon steel outer rings can be pressed around the inner ring, or can have radial splits which would be held together by screws. Inner rings of maintenance-free spherical plain bearings are made of hardened carbon chromium steel, hardened stainless steel, or copper alloy.

The sliding surfaces between these types of spherical plain bearings could have hard chromium plating, PTFE composite, PTFE fabric, or PTFE plastic to reduce wear. Those with copper alloy inner rings will have solid lubricant inserted on the sliding surface. Outer and inner rings can be phosphate coated to increase corrosion resistance. Some bearing designs can also be fitted with seals to keep out contamination. Variations with multiple axial split outer rings can be fitted with retaining rings.

Click on each below to learn more about the variations of maintenance free spherical plain bearings:

- Angular Contact - PTFE Fabric, PTFE Plastic

- Formed Outer Race - Steel-on-PTFE composite

- Stainless Steel-on-PTFE Fabric Material

- Steel-on-Bronze

- Steel-on-Copper Alloy

- Steel-on-PTFE Composite Material

- Steel-on-PTFE Fabric Material

- Steel-on-PTFE Plastic Material

- Thrust Loading - PTFE Fabric, PTFE Plastic

Permissible Operating Temperature Range

The steel-on-steel, steel-on-PTFE composite material and steel-on-PTFE fabric radial spherical plain bearings can be used at temperature -50° C ~ +150° C, The spherical plain bearings with seals can be used at temperature -30° C ~ +130° C. At higher temperature, the load carrying capacity will be reduced.