Last time in the Bearings Blog we looked at what preloading means and why it’s important. To read that post, click here.

In this post, we’ll be taking a closer look at two methods of preloading ball bearings – spring and fixed constraint – and what you need to know about both options.

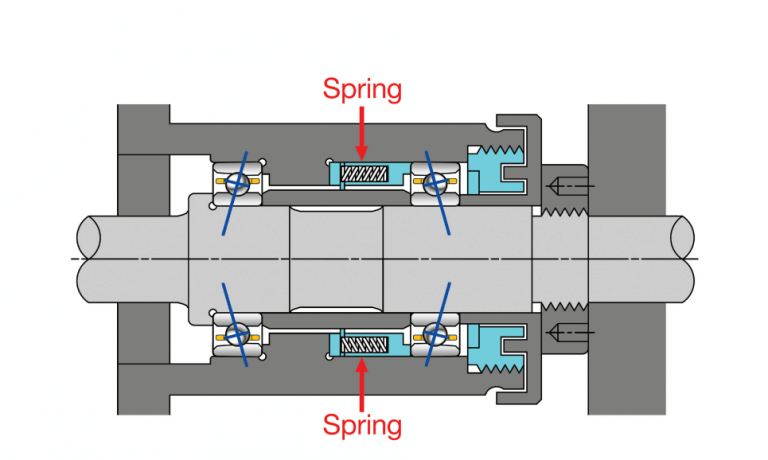

Spring preloading is simple, inexpensive, and should be a designer’s first consideration. Coil springs or wave spring washers are most commonly used, but a variety of spring types are available. The spring is used to press the races together, or apart.

Spring preloading provides a relatively constant preload because it is less sensitive to differential thermal expansion and can accommodate misalignment. Spring preloading uses a floating ring that reduces vibration levels transmitted from the bearings, making it a good choice in noise-sensitive applications. However, these types of assemblies will have minimal stiffness. Usually, the spring is positioned to push against the non-rotating ring.

Fixed constraint preload is achieved by mechanically fixing the “as-preloaded” position of the inner and outer rings of each bearing. This is commonly performed using the dead weight method. With dead weight preloading, adhesive is used to secure the rings in position while held in place with a weight equal to the specified preload amount. Once the adhesive has cured the weight is removed.

Stay tuned for more details on preloading ball bearings here at the AST blog over the next few posts, we have even more details ready for you coming soon! Our next post, scheduled for April 15, will look at two more methods preloading bearings: axial adjustment and duplex bearings. In the meantime, if you would like to speak with a bearing expert about this or any bearing-related topic, please contact us here.