As part of our mission at the Bearings Blog, we strive to delve deep into topics, giving readers a deeper understanding of a topic through in-depth, multi-part series. Some examples of past iterations include our looks into bearings in the medical and food and beverage areas.

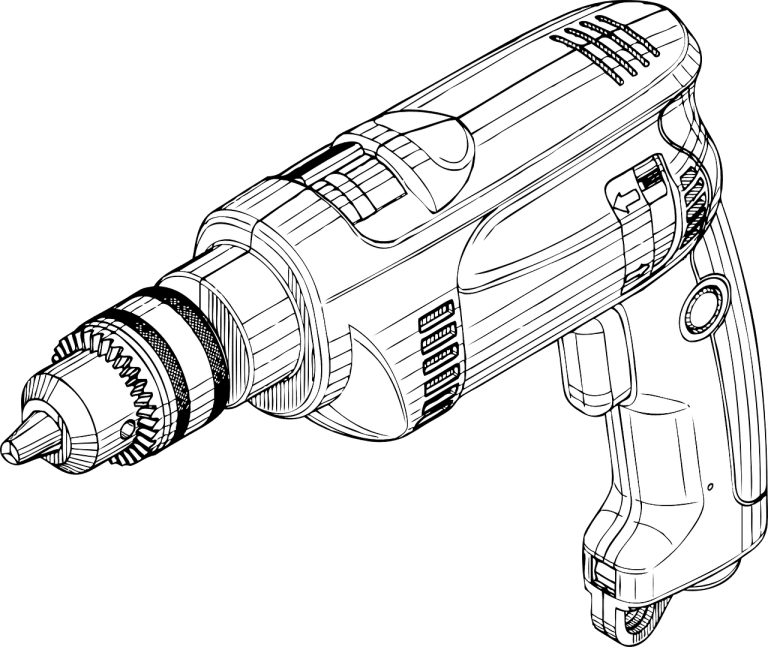

In that spirit, we’re proud to announce the newest industry series that we’ll be publishing over the upcoming several posts: bearing considerations in handheld power tools.

Handheld power tools are ubiquitous in construction, used professional builders and DIYers alike. Ball bearings play a critical role in the performance and reliability of these tools, and are responsible for handling combined loading conditions (radial and axial), high speed operation, low friction, low noise and vibration and high reliability.

Power tools have a global market of close to $26 billion (approximately $11 billion in the US). Cordless electric power tools being the fastest growing segment, with the industrial and professional market outpacing consumer demand. Products produced for the consumer market generally have lower price points, lower quality and incorporate components that are “off the shelf” or fall into the “commodity” category.

In the industrial arena, power tools are highly engineered products that reduce worker fatigue and improve productivity and quality. They are routinely used in all types of operations such as, driving (fasteners), drilling, cutting, shaping, sanding, grinding, routing, polishing and more.

Typical industrial rotary tools include, drills, screwdrivers, nut runners, impact wrenches and drivers, grinders, sanders and polishers. Electric motors and compressed air are the most common types of powers sources used in a factory environment.

Over the next four blog posts we’ll be taking a looks at some of the critical areas of consideration for bearings in these tools. Here’s links to next installments of the series: